B.E Mechanical Engineering

Mechanical Engineering is an engineering discipline that combines engineering physics and mathematics principles with materials science to design, analyze, manufacture and maintain mechanical systems. It is one of the oldest and broadest of the engineering disciplines. The mechanical engineering fields an understanding of core areas. It is the branch of engineering that involves the design, production and operation of machinery. Mechanical engineering emerged as a field during the industrial revolution in Europe in the 18th century.

Our Vision

In order to meet the needs of society, we aim to provide a high quality education in Mechanical Engineering that prepares graduates to be globally competitive and creates cutting-edge research centers that can provide solutions to society's problems.

Mission

- We aim to impart quality education so that we can produce mechanical engineers who are competitive at a global level.

- Our goal is to develop state-of-the-art research facilities in Mechanical Engineering that will enable faculty and students to study, disseminate information, and innovate.

- Developing an entrepreneurial spirit and promoting consultancy among students in order to facilitate the development of their entire personality.

- To improve communication skills for higher education and job placements.

- The goal is to foster teamwork culture and improve social standards and quality of life for graduates.

- To enhance the reputation of the department on the global stage through academic and scholarly activities.

PEOs, PSOs and Pos

Programme Educational Objectives

In their careers, our graduates will :

- Apply fundamental technical knowledge and skills to find workable solutions to technological challenges and problems in core and allied areas of mechanical engineering.

- Design and develop Engineering system components with the sense of ethics, professionalism for the benefit of the industry as well as society.

- Enhance their professional career through continual learning to take-up challenging task in the organization they work with good technical competency, communication skills and team spirit.

Program Specific Outcomes

- Analyze, design and develop machining systems to solve the engineering problems by integrating thermal, design and manufacturing domains of mechanical engineering.

- Adopt a multidisciplinary approach to solve real-world industrial problems.

On successful completion of the Mechanical Engineering Degree programme, the Graduates shall exhibit the following:

- Apply the knowledge gained in Mechanical Engineering for design and development and manufacture of engineering systems.

- Apply the knowledge acquired to investigate research-oriented problems in mechanical engineering with due consideration for environmental and social impacts.

- Use the engineering analysis and data management tools for effective management of multidisciplinary projects.

Program Specific Outcomes

- Effectuating success in careers by exploring with the design, digital and computational analysis of engineering systems, experimentation and testing, smart manufacturing, technical services, and research.

- Amalgamating effectively with stakeholders to update and improve their core competencies and abilities to ethically compete in the ever-changing multicultural global enterprise.

- To encourages multi-disciplinary research and development to foster advanced technology, and to nurture innovation and entrepreneurship in order to compete successfully in the global economy.

- To globally share and apply technical knowledge to create new opportunities that proactively advances our society through team efforts and to solve various challenging technical, environmental and societal problems.

- To create world class mechanical engineers capable of practice engineering ethically with a solid vision to become great leaders in academia, industries and society.

Program Outcomes

- Apply basic knowledge of mathematics, science and engineering principles to solve technical problems.

- Design and analyze a system component, or process to meet desired needs in Mechanical Engineering.

- Design a system and conduct experiments to find suitable solution in the field of mechanical engineering.

- Identify, visualize, formulate and solve engineering problems in the field of mechanical Engineering.

- Use the techniques, skills, and modern engineering tools necessary for engineering practice with appropriate considerations for societal and environmental constraints.

- Apply their fundamental field skills towards the understanding of the impact of engineering solutions on the society in a global and social context.

- Impart knowledge of contemporary issues about society and environment.

- Apply ethical principles and responsibilities during professional practice.

- Function on multi disciplinary teams as a team member/leader and create user friendly environment.

- Communicate effectively in oral, written, visual and graphic modes within interpersonal, team, and group environments.

- Apply the techniques, skills and modern engineering tools necessary for engineering projects.

- Recognize the need for professional advancement by engaging in lifelong learning.

Faculty Profile

| Name | Designation | Qualification | Experience | Specialization | Photo | |

|---|---|---|---|---|---|---|

| Dr.N.Senthil Kumar, PhD | Professor & HoD | M.E, PhD, | 17 Years | senthilmech@avstech.ac.in | Product Design & Development, Industrial Engineering, Customer Relation Management |  |

| Dr S Karthick | Assistant professor | M.E. Ph.D. | 11 year(s) 9 month(s) | karthickmech@avstech.ac.in | Production, Material science, Welding, Optimization. |  |

| S Shanmugam | Assistant professor | M.E, PhD, | 11 year(s) 10 month(s) | shanmugammech@avstech.ac.in | Engineering Design, Nano Coating, Composite Materials & Optimization. |

|

| Mr.H.Devendiran | Assistant professor | M.E | 8 years | devamech@avstech.ac.in | Manufacturing |

|

| Mr. B NAGENDIRAN | Assistant professor | M.E | 6 year(s) 9 month(s) | nagendiranmech@avstech.ac.in | Product design and development, engineering design. |

|

| Mr. S SURYA | Assistant professor | M.E | 7 year(s) 11 month(s) | suryamech@avstech.ac.in | Thermal Engineering , engineering design. |  |

| M.Senthilkumar | Assistant professor | M.E | 15 years | senthilkumar@avstech.ac.in | Engineering Design. |

|

| Chakravarthi R | Assistant professor | M.E | 7 years | chakaravarthimech@avstech.ac.in | Thermal Engineering. |

|

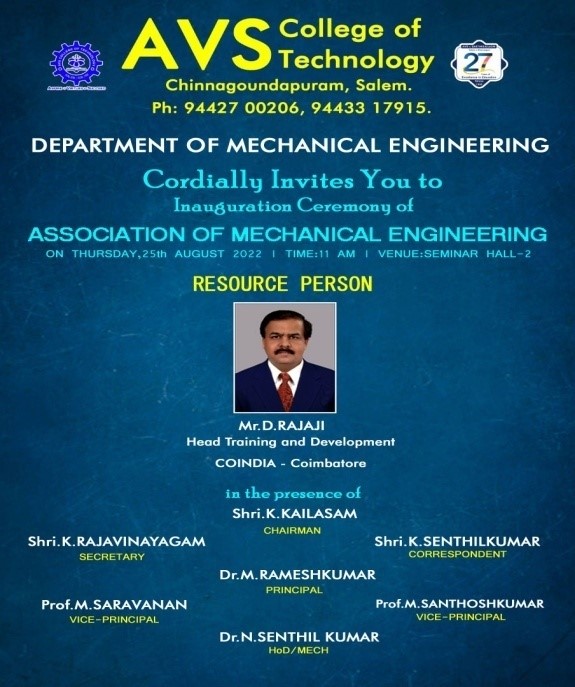

Association

Title: Department Association Inauguration

Date/Time: 25.08.2022/11AM to 12.30PM

Resource Person: Mr.D.RAJAJI, Head Training and Development, COINDIA, Coimbatore.

Guest Lectures, Seminars & FDP

Product Design and Development strategy.

26.10.2022 / 10AM to 5.00PM

Seminar

This seminar gives the overview of product design, skills required to be a designer and how to take an idea from concept to market stage.

| Resource Person |

|---|

| Dr.Venkatesan, Propreitor, Core Innovation Solutions, Salem. |

| Coordinator | Department |

|---|---|

| Mr.Chakravarthy | AP/Mech |

VENUE: Seminar Hall 1

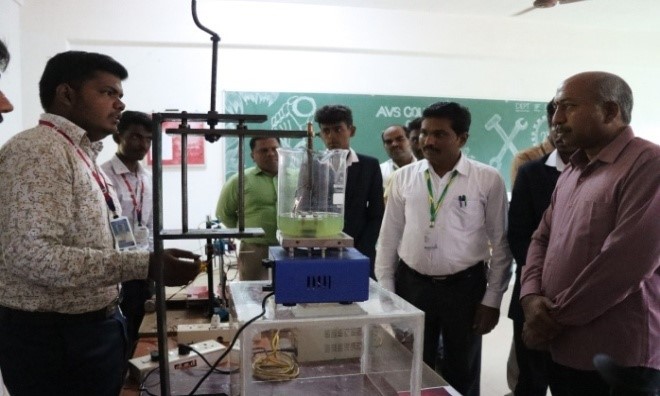

Project Expo

02.11.2022 / 10AM to 5.00PM

The department of Mechanical Engineering organized Project Expo-The Idea Explorer for our students. It provided a platform for the students to showcase their talents and celebrate their success. A total of 20 teams participated and exhibited their novel ideas through presentation and project demo in various emerging streams.

| Resource Person |

|---|

| Er.P.Balasubramani, B.E. Superintendant, SEDC, Salem |

| Coordinator | Department |

|---|---|

| Mr.S.Kannan | AP/Mech |

VENUE: Seminar Hall II

Robotics

29.10.2022/10.00AM to 1.00PM

Faculty Development Program

The FDP aimed to make the participants aware of the robotics field. It comprises the essentioal theory with hands on experiments on different simulation software by the experts from academic institutions to improve teaching quality to motivate students in this interdisciplinary field.

| Resource Person |

|---|

| Venugopal Parvatikar |

| Coordinator | Department |

|---|---|

| Mr.S.Karthick | AP/Mech |

VENUE: Sona College of Technology.

Design thinking of Entrepreneurs

09.10.2022/ 10AM to 5PM

Workshop

Students from our institutions displayed their ideas and prototypes and interacted with Business plans. Executives from industries and representatives from other also Institutions attended the event. Providing possible future tie ups among industry and institutions in the field of research &innovation, internship, skill training etc.

| Resource Person |

|---|

| Mr.Vishal Nair, Master Trainer, EDII – TN. |

| Coordinator | Department |

|---|---|

| Dr.N.Senthilkumar | HOD/Mech |

VENUE: EDI, Sona College of Technology

Entrepreneurship Development

16.10.2022/10AM to 5.00PM

Faculty Development Program

The programme is designed to train and develop professionals in the area of Entrepreneurship Development so that they can act as ‘Resource Persons’ in guiding and motivating young students, particularly from science & technology stream, to take up Entrepreneurship as their career.

| Resource Person |

|---|

| Mr.Gowtham, EDII Coordinator, Sona Hub. Salem. |

| Coordinator | Department |

|---|---|

| Dr.N.Senthilkumar | HOD/Mech |

| Mr.B.Nagendiran | AP/Mech |

VENUE: EDI, Sona College of Technology

Entrepreneurship Development Stalls

02.11.2022 / 10AM to 5.00PM

Engineers Day Celebration

Engineers’ Day is celebrated every year on September 15, the birth anniversary of Sir M. Visvesvaraya, known as the Father of Engineering, in order to commemorate his contributions to the field of engineering in India. He is credited with having built the Krishnaraja Sagar Dam in Karnataka and designed flood prevention systems in that state.

| Resource Person |

|---|

| Er.D.Pushpalatha, M.E. Executive Engineer, SEDC, Salem. |

| Coordinator | Department |

|---|---|

| Mr.Chakravarthy | AP/Mech |

VENUE: Seminar Hall 1

On Job Training Session

29.09.2022/10.30AM to 5 PM

Industrial Visit

Program includes providing them with a license. They trained 50 students, from the Government of Tamil Nadu Skill Development Scheme. Since it is free of cost, people are willingly taking part in such programs now provided certificates on completion of these courses which helps the Students to get placed immediately. Also to address the problem of reckless driving and on road safety for students also.

| Resource Person |

|---|

| Er.Balakumaran.V, Head DTI, Namakkal. |

| Coordinator | Department |

|---|---|

| Mr.B.Nagendiran | AP/Mech |

| Mr.S.Kannan | AP/Mech |

VENUE: Ashok Leyland Training Unit, Namakkal

TECHFEST

19.10.2022 /10 AM to 5 PM

Symposium

The TECHFEST 2K22 Symposium is the open scientific symposium focused on the mechanical department. It offers a unique, region wide knowledge exchange, capacity development, strategic action and cooperation. Symposium is the largest with an expected 60 people attending in person. The Symposium is an opportunity to showcase innovative solutions for addressing the challenges facing mechanical stream.

| Resource Person |

|---|

| Dr.RAMESHKUMAR Principal, AVS College of Technology |

| Coordinator | Department |

|---|---|

| Mr.Nagendiran | AP/Mech |

VENUE: AVS College of Technology

Seminar on Non Destructive Testing

17.09.2022/11AM to 12.30PM

Student Interaction Program

The Student had very good interaction with Institute through an expert on Various Topics Like,

- Training and Placement activities.

- Industrial Training and Internship Activities.

- Carrier oriented training session.

| Resource Person |

|---|

| Mr.M.MAHENDRA PERMUAL, General Manager, Intergity Inspection Services, Salem. |

| Coordinator | Department |

|---|---|

| Mr.G.Pradeep Kumar | AP/Mech |

| Mr.S.Surya | AP/Mech |

VENUE: Seminar Hall I

Industry 4.0

03.11.2022/10.00AM to 1.00PM

FDP

The FDP aimed to explore and bring awareness with promising outcomes towards the innovative teaching, learning and teaching practices. Helpful to faculty members, researchers and professionals to update themselves about the research avenues and challenges in the field of interdisciplinary engineering.

| Resource Person |

|---|

| Sarangarajan V |

| Coordinator | Department |

|---|---|

| Dr.N.Senthilkumar | HOD/Mech |

VENUE: Sona College of Technology.

Workshops

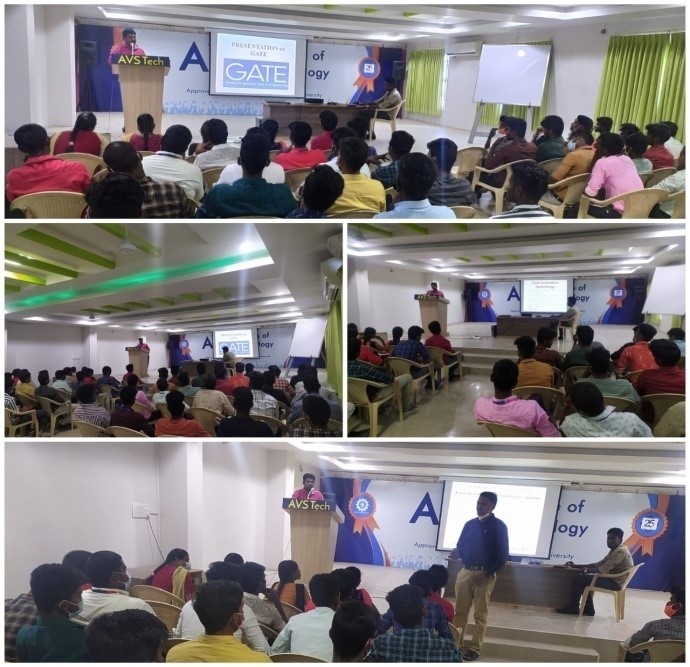

1. Spark Gate Academy

The Mechanical department has organized an interaction session about Gate Exam preparation for II, III and IV Year students. (22-03-2022)

Date: 22.03.2022

Time: 02.00 PM to 03.00 PM

Resource person: Mr.Venkatesan.

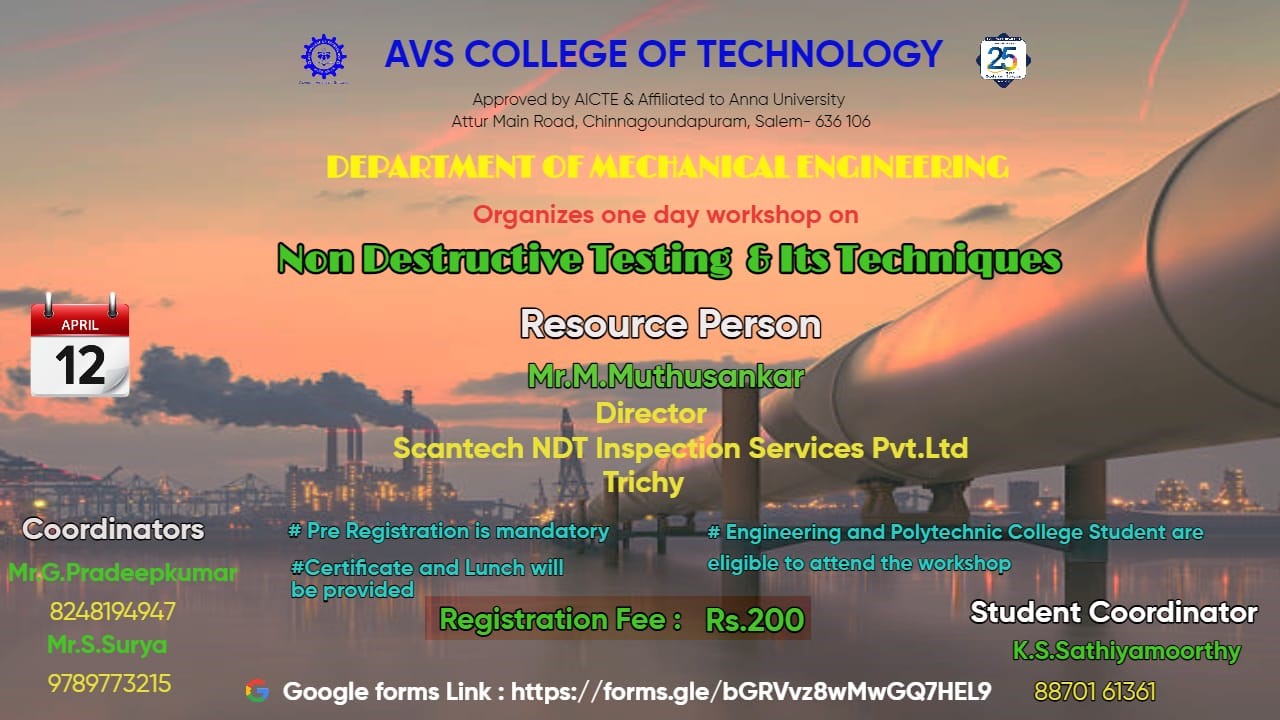

2. Workshop On Non Destructive Testing And Its Techniques

Department of Mechanical Engineering is organizing a Workshop on "Non Destructive Testing & Its Techniques”

Date: 12.04.2022

Time: 10.00 AM to 04.00 PM

Mr. M.Muthusankar, Director, Scantech NDT Inspection Services Pvt.Ltd, Trichy.

Industrial Visit

| S.NO | Name of organization | Address of organization | Number Of Student Participated | Period of internship | Photo |

|---|---|---|---|---|---|

| 1 | Salem Material and Technology | Sidco, women industrial park, Karuppur, Salem 636011, Tamil Nadu | 06 | Start Date: 23.06.2023 to End Date : 07.07.2023 |  |

| 2 | Ess vee wires India private limited | Sidco, women industrial park, Karuppur, Salem 636011, Tamil Nadu | 10 | Start Date: 23.06.2023 to End Date : 07.07.2023 |  |

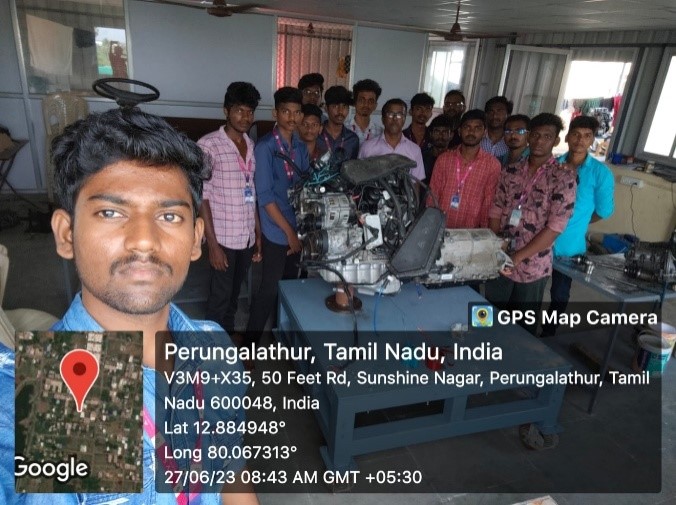

| 3 | GOODWIN MOTORS | Plot No.10, Subhamangala Avenue, Mannivakkam Extn, Chennai - 600 048 | 25 | Start Date: 16.07.2023 to End Date: 30.08.2023 |  |

Events

1. Tamilnadu State Karate Championship -2021

Mr. M. Govindharaj , III year, Mechanical Engineering student won the 3rd prize in the " Tamilnadu State Karate Championship -2021 " under - 21 (M) - 60kg.

B.E MECHANICAL ENGINEERING

Download your MECH Syllabus & Study Materials of Regulations - 2017 & 2021

Syllabus

Study Materials R-2021

Download Semester 1 all Study Materials Click Here

Download Semester 2 all Study Materials Click Here

Download Semester 3 all Study Materials Click Here

Download Semester 4 all Study Materials Click Here

Download Semester 5 all Study Materials Click Here

Download Semester 6 all Study Materials Click Here

Download Semester 7 all Study Materials Click Here

Download Semester 8 all Study Materials Click Here

MOU’s

1. MOU with Salem Aeropark Group

This Memorandum of Understanding executed at Salem on 8th December, 2021. Between The Salem Aeropark Group, Salem has made a name for itself in the list of top suppliers of aerospace companies in India having its Administrative Office at “NH 7, Ammapalayam Village, Mallur, Salem, Tamil Nadu - 636203” where the context so admits mean and include its successors-in-interest and permitted assigns, represented herein by its Authorized Signatory, The General Manger Shri.R.K.Jawaharlal. And AVS College of Technology was established to render educational services to the students and faculty duly formed and registered under the AICTE New Delhi and Affiliated to Anna University, Chennai having office at Chinnagoundapuram, Salem (Dt), Tamilnadu and was established in the year 2013 referred to as ‘AVS Tech’ which expression unless repugnant to the context or meaning thereof, be deemed to include its successors- in- interest and permitted assigns, represented herein by its Authorized Signatory, The Secretary Mr.K.Rajavinayakam.

2. MOU with Shri Sai Institute of NDT & Inspection Services

Dear All, Warm Greetings from AVS COLLEGE OF TECHNOLOGY, Salem. Department of Mechanical Engineering. We are Very Happy to Inform you that our department has signed the MOU with Shri Sai Institute of NDT & Inspection Services, Puducherry On 10.01.2022 Thank you…

3. MOU with M/S. Flexitim Engineering Solutions

Greetings from AVS College of Technology, Salem. The department of Mechanical Engineering has organized the Guest Lecture Programme on Scope of Mechanical Engineering for the first year students and also the department signed the MOU with M/S. Flexitim Engineering Solutions on 30.12.2021. Thanks.

Publications

1. Dr.N.Senthil Kumar., ASP/Mech

- N.Senthil Kumar, (2022) “Multi-criteria optimization of tensile and wear behavior of AI7075-sic metal matrix composites by stir casting method using TOPSIS”. Advances in materials and processing Technologies (Taylor and Francis):. Paper Accepted for publication.

- S Raja., Selvarajan L., N.Senthil Kumar, R.Sasi Kumar and S Sadhish Kumar (2022) “Investigation of Welding Speed on Tensile Strength of MIG Welded Hastelloy C-276 joints”. AIP: Publishing,. Paper Accepted for publication

- Selvarajan L.,K Venkataraman., N.Senthil Kumar, R.Sasi Kumar and A Aravindhan (2022) “Investigation and Optimization of EDM parameters of Conductive Ceramic Composite. A Review”. Springer series, journals.

- Selvarajan L., N.Senthil Kumar ,Raja, R.Sasi Kumar and V.Muralidharan (2021) “Effect Of Process Parameter on Performance Measures in Electrical Discharge Machining Using Copper and Brass Electrodes ”. Materials Today: Proceeding. Volume 46, Part 19, 2021, Pages 9257-9262.

- Selvarajan L., R.Sasi Kumar, N.Senthil Kumar, PrabuKolochi and Naveen Kumar (2021) “Effect of EDM Parameter on Material Removal Rate, Tool Wear Rate and Geometrical Errors of Aluminum Material”. Materials Today: Proceeding. Volume 46, Part 19, 2021, Pages 9392-9396.

- Senthil Kumar N & Selladurai V 2018, ‘Positioning and Product Design Drivers of Indian start-up Insurances using Fuzzy Dematel and Topsis Approach: The changing paradigm of advertising and service marketing standards’, Taga Journal of Graphic Technology, vol. 14., paper no.95, 2018.

NATIONAL JOURNAL:

- Senthil Kumar N & Selladurai V 2017, ‘Customer Preference and Product Configuration through Design and Implementation of Fuzzy Dematel and Topsis Approach in Multi Clean Industries in Indian Milieu’, Indian Journal of Scientific Research,vol.17,no.1,pp. 156-163

2. Dr.N.Senthil Kumar., ASP/Mech

- T Ramanathan, K Sekar, N Shanmugam “ Microstructural evaluation and effect of heat generation in fsw of aa1100 br” chiang mai journal of science 49 (2), 487-495

- R Thirumalai, S Karthick, M Giriraj “Microstructural analysis and optimization of welding parameters for AA1100 welded plates” Journal of Ceramic Processing Research “ volume 23 (2), page 221-227

- T Ramanathan, N Shanmugham, K Sekar “Investigation of Welding Process Parameters In Friction Stir Welding of AA1100 Alloy Using Taguchi Technique” chiang mai journal of science 49 (5), 1416-1427

- Karthick S, Girimurugan R, Bensamraj “Experimental investigation and optimization of welding process parameters during friction stir welding of AA1100 using response surface methodology” Journal of Ceramic Processing Research. volume 23 (no. 4,), pp. 553-557

- R Thirumalai, S Karthick, R Ranjith, KMS Kumar “Characterization of Friction Stir Welded AA1100 Aluminium Alloy for High Temperature Application” Solid State Technology 63 (5), 7171-7184

- S Karthick, R Thirumalai “ Friction stir welding of Aa1100 aluminium alloy Advances in Natural and Applied Sciences” 10 (6 SE), 57-67

3. Dr.N.Senthil Kumar., ASP/Mech

- Shanmugam, S,Mahalingam, S &Ranjithkumar, A 2023, ‘Development of Ni - Nano Al2O3 coated AISI1018 mild steel composites via pulse electro deposition and investigation of its wear and corrosion behavior’. Journal of Ceramic Processing Research, vol. 24, no. 3, pp. 495-502. Impact Factor: 0.636.

Department Research

Department Library

Gallery